Electrodialysis

Next-gen solutions for global industries

Captura’s high-performance bipolar membrane electrodialysis technology is now available for commercial production. Pioneered at Caltech and manufactured at Captura’s production facility in Pasadena, California, this advanced system delivers up to 10 times the performance of leading alternatives—at significantly lower energy and capital costs with exceptional lifetime.

Originally developed to power Captura’s Direct Ocean Capture systems, this proprietary electrodialysis platform is now available to a wide range of industries. Combined with a vertically integrated production approach, Captura’s technology delivers exceptional efficiency, scalability, and cost-effectiveness—setting a new industry standard for electrodialysis solutions.

Performance

Advanced stack. Superior membranes.

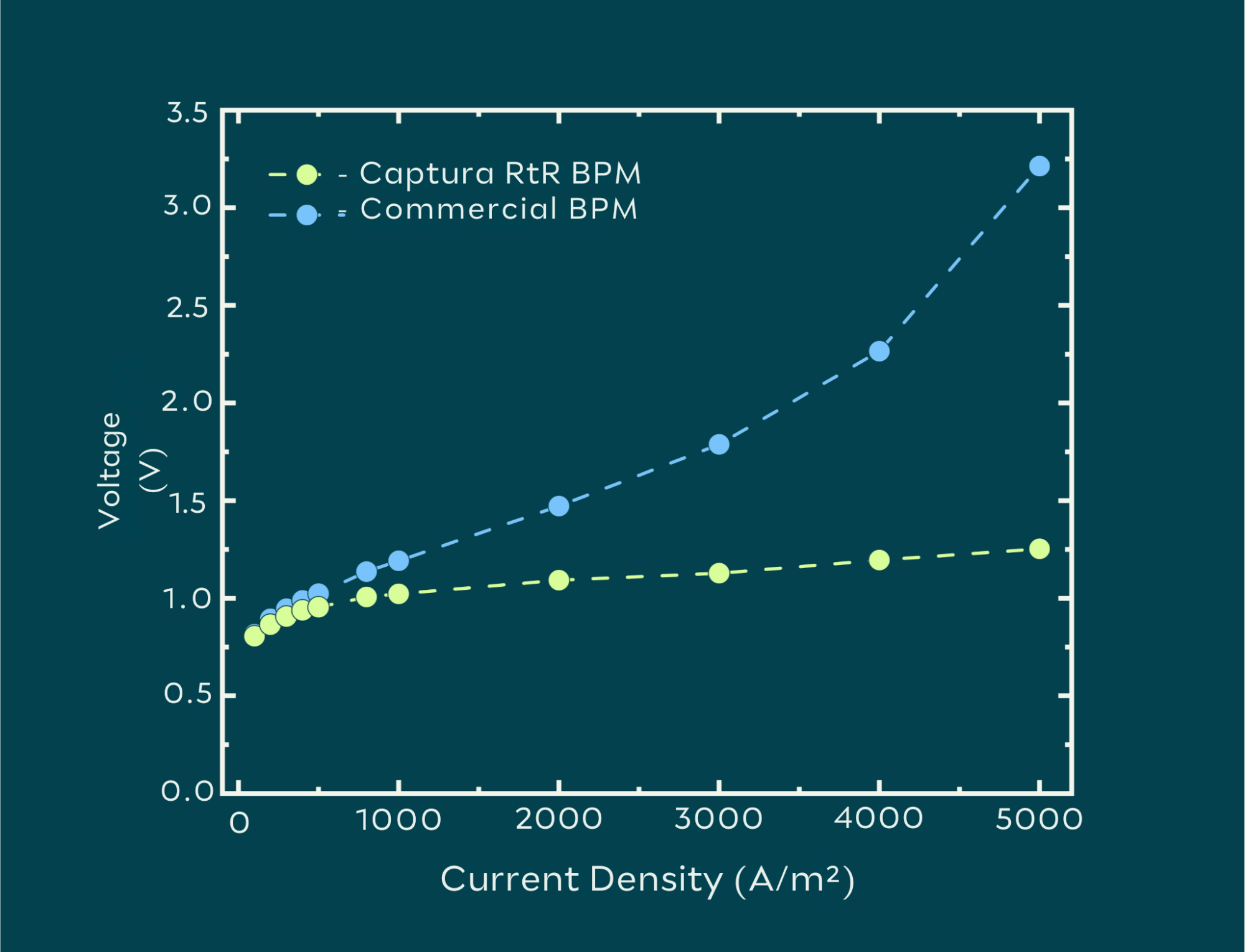

Figure 1: Comparison of Captura’s BPM produced by roll-to-roll (RtR) casting versus standard commercial BPM in Captura’s test station

Bipolar membrane electrodialysis is a separation process that uses a specialized stack of ion-exchange membranes and electrical current to split salt water into acid and base. It is used widely across a variety of industries including desalination, wastewater treatment, critical mineral extraction, life sciences, and electrochemical carbon capture and carbon removal.

Captura’s electrodialysis platform combines high-efficiency, PFAS-free bipolar membranes (BPM) with an advanced stack design, delivering breakthrough performance. To maximize efficiency and minimize costs, stable operation of the membrane system at high current densities and low voltages is critical. Captura’s BPM operate at ultra-high current density and low voltage (close to the thermodynamic limit) while maintaining exceptional stability.

The use of low-cost, highly conductive polymer materials further contributes to energy efficiency, cost-effectiveness, and long-term reliability.

In tests performed by Captura, commercial membranes tend to significantly increase in energy consumption as current density increases. Captura’s proprietary solutions do not have this characteristic and perform close to the thermo-dynamic limit even as current density increases, as shown in Figure 1.

CAPABILITIES & ADVANTAGES

01 End-to-end vertical integration

Captura electrodialysis systems are developed and manufactured through a fully integrated process—from raw materials to field validation. This ensures consistent quality, reduced production and supply chain costs, and a scalable, reliable solution ready for industrial use.

Materials to membranes: We formulate and produce PFAS-free bipolar and other ion-selective membranes in-house using roll-to-roll coating. Each cycle – from polymer synthesis to functional membrane – is measured in days, not months.

Membranes to commercial stacks: Proprietary flow-field designs scale seamlessly from lab units to >300-cell commercial stacks. No third-party hand-offs. No scale-up surprises.

Real time field feedback: Our pilots stream live operational data back into R&D – linking field performance to lab improvements in near real time; shortening the path from hypothesis to validated system.

02 Accelerated R&D engine

Captura is purpose-built to turn scientific breakthroughs into deployable, customized solutions—fast. Our agile, cross-functional teams and integrated, scalable infrastructure enable us to rapidly tailor electrodialysis systems to meet specific industrial needs.

Production-ready testing: Full-scale diagnostic stack testing at MW-class equivalent conditions ensures real-world readiness.

Integrated development pods: Chemistry, diagnostics, stack and system teams collaborate to accelerate iteration cycles and delivery timeline.

Scalable infrastructure: We operate across all relevant scales – grams to kilograms of custom polymers, square-meters to thousands of square-meters of membranes, and lab tests to full-stack systems – all under one roof.